Share

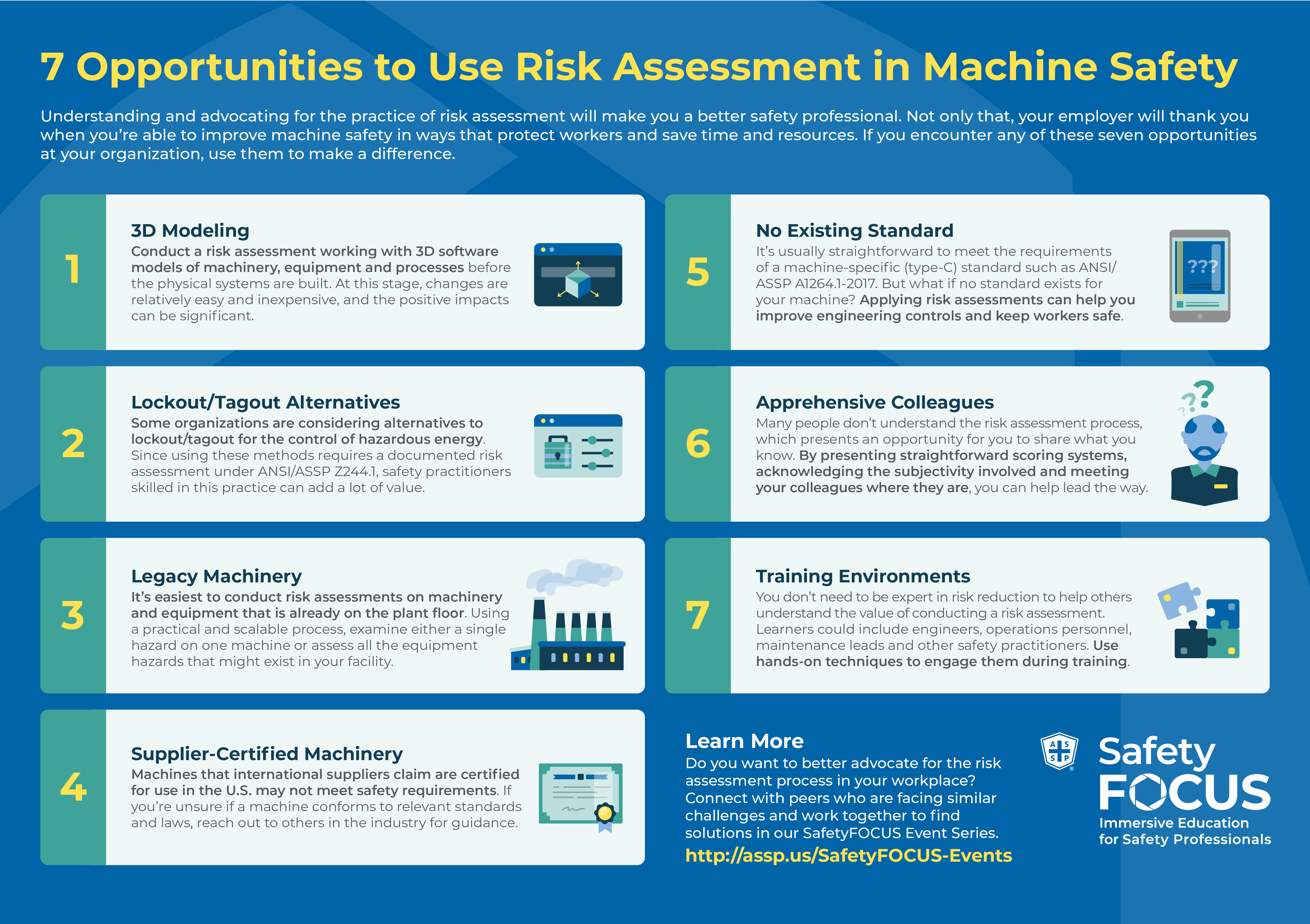

Understanding and advocating for the practice of risk assessment will make you a better safety professional. Not only that, your employer will thank you when you’re able to improve machine safety in ways that protect workers and save time and resources. If you encounter any of these seven opportunities at your organization, use them to make a difference.

Conduct a risk assessment working with 3D software models of machinery, equipment and processes before the physical systems are built. At this stage, changes are relatively easy and inexpensive, and the positive impacts can be significant.

Some organizations are considering alternatives to lockout/tagout for the control of hazardous energy. Since using these methods requires a documented risk assessment under ANSI/ASSP Z244.1, safety practitioners skilled in this practice can add a lot of value.

It’s easiest to conduct risk assessments on machinery and equipment that is already on the plant floor. Using a practical and scalable process, examine either a single hazard on one machine or assess all the equipment hazards that might exist in your facility.

Machines that international suppliers claim are certified for use in the U.S. may not meet safety requirements. If you’re unsure if a machine conforms to relevant standards and laws, reach out to others in the industry for guidance.

It’s usually straightforward to meet the requirements of a machine-specific (type-C) standard such as ANSI/ASSP A1264.1-2017. But what if no standard exists for your machine? Applying risk assessments can help you improve engineering controls and keep workers safe.

Many people don’t understand the risk assessment process, which presents an opportunity for you to share what you know. By presenting straightforward scoring systems, acknowledging the subjectivity involved and meeting your colleagues where they are, you can help lead the way.

You don’t need to be expert in risk reduction to help others understand the value of conducting a risk assessment. Learners could include engineers, operations personnel, maintenance leads and other safety practitioners. Use hands-on techniques to engage them during training.

Learn More

Do you want to better advocate for the risk assessment process in your workplace? Connect with peers who are facing similar challenges and work together to find solutions in our SafetyFOCUS Event Series.

http://assp.us/SafetyFOCUS-Events

For more insight into these seven possible scenarios, read “New Opportunities in Safety: Lessons From a Risk Assessment Journey” in the April 2020 issue of Professional Safety.

Gain the technical resources, community and continuing education units (CEUs) you need to stay ahead. Join your peers at SafetyFOCUS.

Back to home page Read next article